Introduction

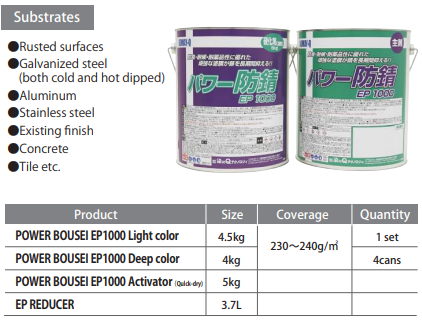

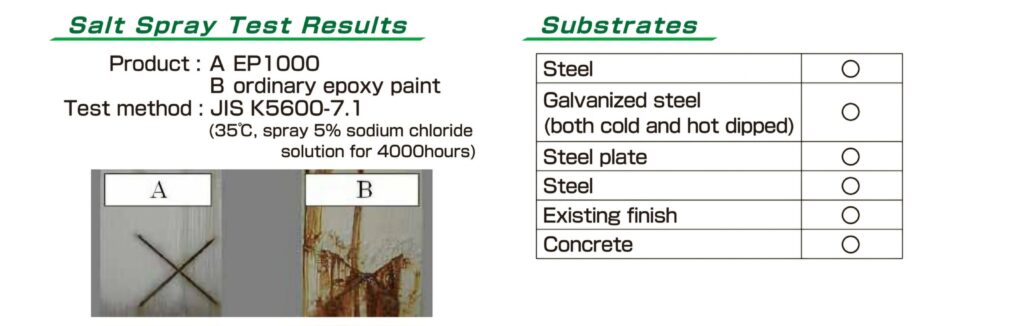

Power preventive EP1000 can apply directly on various surfaces such as rusted surface, galvanized steel (cool and hot dipped), aluminum, concrete, tile, steel plate, chemical composition, existing finish. It can build dry film thickness over 75-150u per coat. Especially, it can adhere to serious rusted surface with minimum surface preparation. It is a high solid modified epoxy topcoat which provides VOC compliant and high penetration power.

Remarkable characteristics

- Not required for undercoating and top coating! Excellent rust preventive with just EP 1000;

- Thick coat up to 75 – 150µ dry film thickness perr coat;

- Minimum surface preparation (SSPC-P-2);

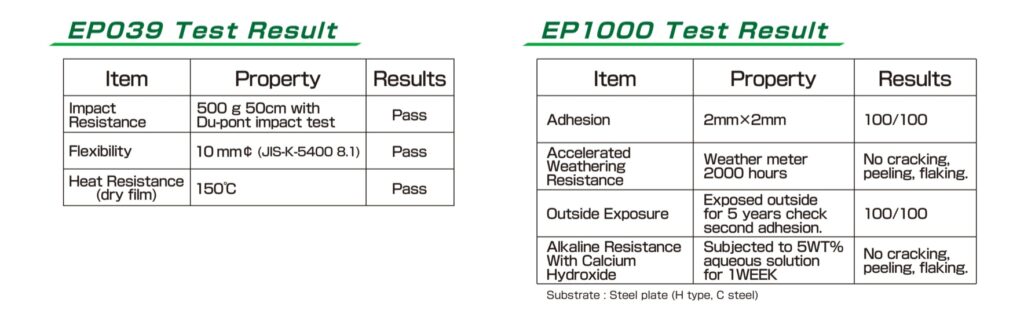

- Excellent resistance to chemical, moisture and friction;

- Can apply it as under coat. Compatible with many topcoats for various substrates.

Technical parameters

Direction for use

Step 1. Remove loose rust with a common tool such as a hammer. Then perform minimum surface preparation (SSPC-SP-2) with sandpaper or wire brush.

Step 2. Remove surface of all contaminants including dirt, chemicals, oil, grease, seawater, alkalis and acids. Rinse thoroughly with fresh water. Allow todry completely.

Step 3. Mixing.

a. Thoroughly mix base component.

b. Thoroughly mix activator.

c. Mix base component and activator at 1:1.1 ratio by volume.Mix base component and activator at 1:1.25 ratio by volume.

d. Thoroughly mix for 3 to 5 minutes.

Step 4. Apply with airless spray, roller or brush.

Step 5. After using, wash equipment and containers with reducer or thinner.

※ Exposure to sunlight and the elements can cause fading, yellowing and chalking. But the corrosion resistance will not be adversely affected.

※ Beware of low curing temperatures and condensation on the film while curing because they can cause blushing.

Notes:

- In most cases, EP1000 can be applied immediately aftermixing. In cold emperatures, allow 30 minutes before applying.

- Keep container closed when not in use. Activator must beused within 1‒2 months.

- If necessary, reduce 10% by volume with urethane reducer.

- Apply it at more than 10C within 80% humidity.

- Apply on edge and volt with brush beforehand.

Tiếng Việt

Tiếng Việt 日本語

日本語