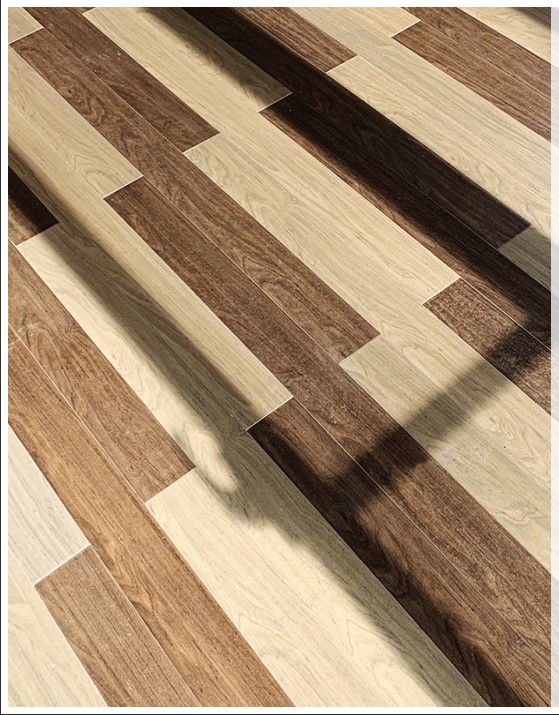

MOZOWOOD is made from smashed recycled plastic waste, no other wastes such as wood chips and textile fibers. Nearly 20 metric tons of a decade-old tree can be saved in every 1 ton of MOZOWOOD materials produced. In essence, this composite plastic imitation wood is a granular elastomer that is able to be applied to any general wood-working method.

Safe for users: Non-toxic, odorless, free of heavy metal residues, no glass fiber debris (a cause of respiratory, allergic dermatitis).

Properties:

- High rigidity (more harshness than other eco-friendly plastic wood on the market);

- Good resistance;

- Strong nail pulling force;

- Resistant moisture;

- Inorganic antibacterial ability;

- Endless life circle.

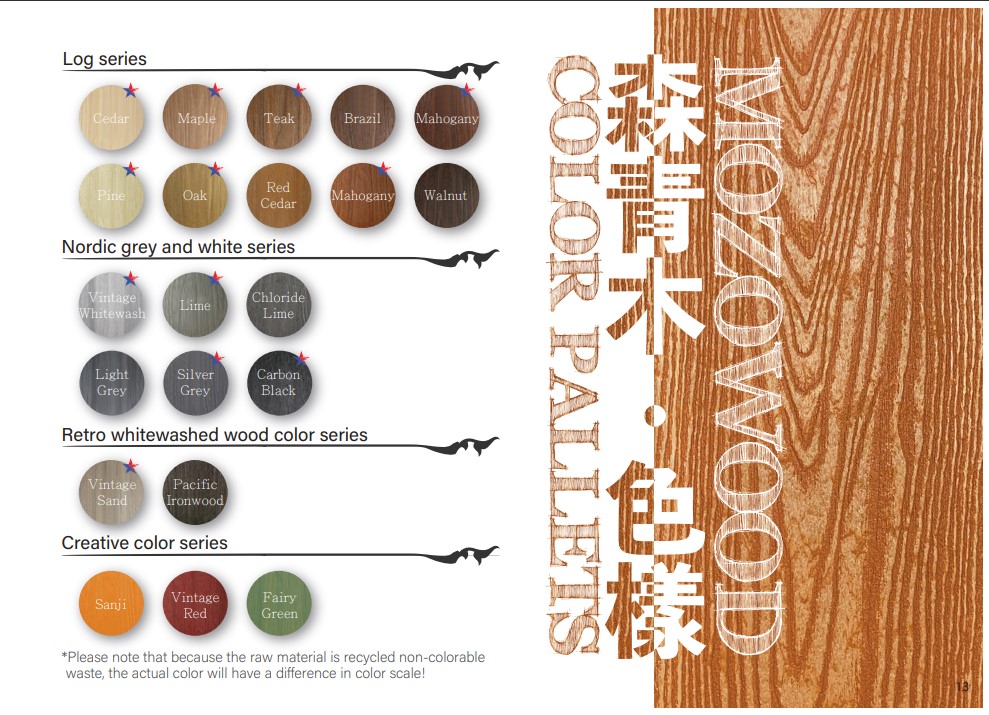

Colors: log (cedar, oak, teak, …), nordic gray and white (lime, carbon black, …), retro whitewashed wood, and many more

Applications: building materials for indoor and outdoor construction and decoration needs such as interior decoration, partition wall, ceiling, transfer floor, boardwalk/terrace,…

Production: Made in Taiwan based on Japanese technology. MOZOWOOD products were used in many countries but currently not in Vietnam. This is the first time introducing MOZOWOOD in Vietnam’s market.

Eco-friendly: non-polluting process, recycling of old materials and scraps, strong endurance.

International certification: SGS inspection

Please contact us for more details!

Tiếng Việt

Tiếng Việt 日本語

日本語

Pingback: Plastic waste-recycled Mozowood: Online Discussion with the Manufacturer - Solen