The following article presents the carbon brick product of a startup company in India. Their goal is to help clean up the air of cities in India, one of the countries with very poor air quality. And further is the desire to create a step forward in construction development in a sustainable way.

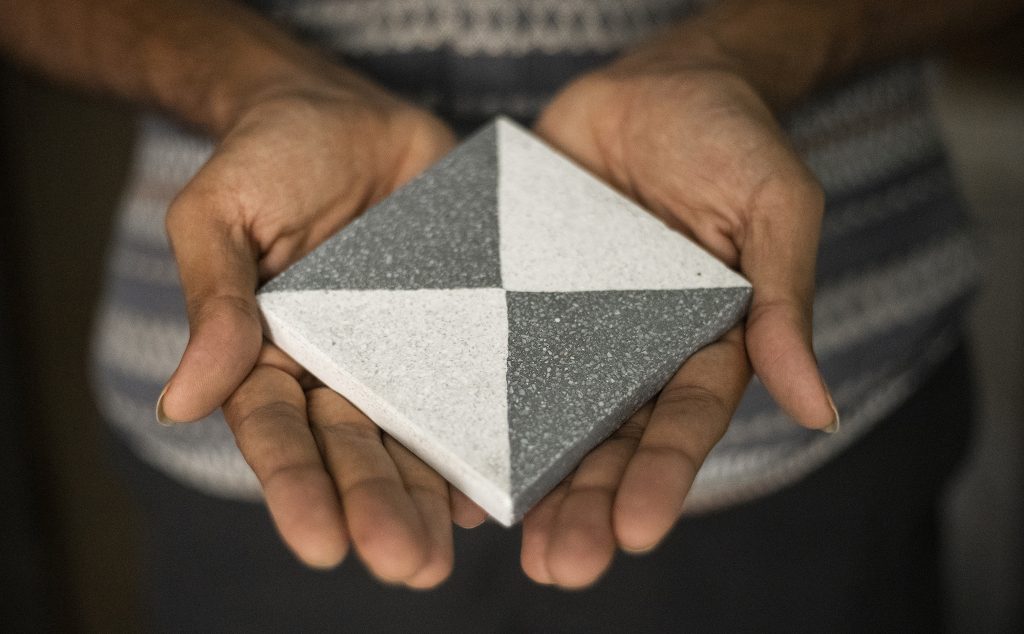

Below are bricks produced from dust.

Black soot from flue gas sources is used to produce carbon bricks. The founders of the Indian company bring us a new solution for reducing air pollution and possibly a potential solution in the new era of sustainable buildings. But how from small dust particles in the air produce floor tiles or cement? And does this make a difference to a country with the worst air quality in the world?

So why is India’s air quality so bad? The first is the source of household emissions; many people use wood and animal manure for cooking in the house, creating a lot of smoke. Next is the source of emissions from traffic. The number of cars on the road has quadrupled since 2003. Air pollution is worst starting in winter. That’s when farmers burn waste, agricultural by-products. Air pollution-related diseases kill more than 1 million people in India each year. This figure is 10 to 20 times higher than in the United States. The good news is that carbon black is short-lived. It only stays in the air for a few weeks. Unlike CO2, a colorless gas that has caused global warming for centuries. The problem is that people in India burn so many things the air doesn’t have time to diffuse pollutants (self-cleaning). Therefore, preventing black soot at the source of emissions can be a solution that should be considered. That was the big idea of Tejas Sidnal, an architect and inventor of carbon bricks.

Black carbon comes from burning fossil fuels. The emission of large amounts of black carbon makes the city sky in India seriously polluted. Black carbon is known to be a respiratory hazard, reduces crop yields, and contributes to global warming.

Tejas Sidnal is the inventor of carbon brick, launching Craft Design in 2020 to create a commercial product produced from waste. Tejas’ carbon source mostly comes from companies that emit black soot sources and companies that often sell it as a cheap fuel. Carbon bricks made from materials from black soot do not have to go through a high-temperature kiln firing process like other paving bricks, so the production process of this material does not require much energy.

Tejas’ unit takes orders for production. With the production process almost the same as other types of paving bricks, they only replace some cement components with carbon black. The production unit has added white marble powder, carbon black, and other fillers to the mixer, and the machine will rotate and mix the ingredients for half an hour.

Tiếng Việt

Tiếng Việt 日本語

日本語